Sub-X™-20K

The Next Generation of Subsea Gasket Technology

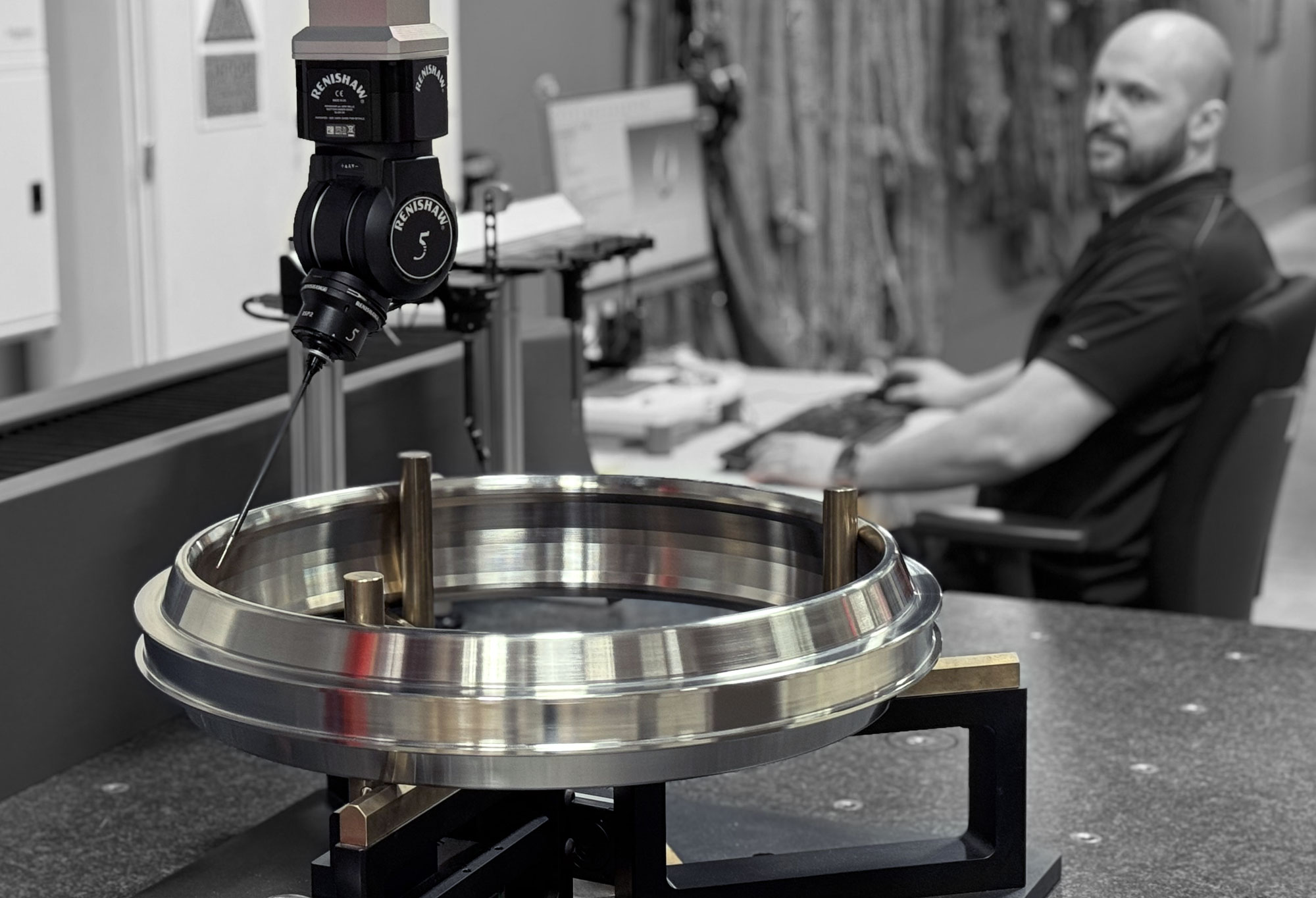

Sub-drill has completed the first PR2-F qualification of a 20K Sub-X™ Subsea Gasket to the most stringent industry qualification standards. Sub-drill’s qualified 20K Sub-X™ Gasket design is destined for use in a new generation of 20,000 psi BOP’s, Wellheads and Production Systems that are required to tackle the most extreme high pressure and temperature wells in the deepest parts of the oceans.

The sealing technology used to develop our first Sub-X™-20K subsea gasket is the result of years of research, development and testing which has given a valuable insight into the behaviour of metal seals under different sealing environments. Our understanding of gasket behaviour and the unique sealing technology developed during our R&D project, along with over 30 years of experience designing and manufacturing subsea seals, has led to the successful development of the first in a range of Sub-X™-20K gaskets to be added to the Sub-X™ Subsea Gasket range.

Mark Paton, Managing Director of Sub-drill, reflects on the significance of this achievement: “Achieving innovation in any particular discipline can only be achieved with a fundamental understanding of what has gone before and an expectation of where you see it going. Some of the most significant advances in Oil and Gas Technology have been created by thinking outside of the box and our journey to create and manufacture a market leading range of subsea gaskets has been no different. There have been many challenges to overcome during the development of our Sub-X™ subsea gasket range and the challenges faced while developing our first 20,000 psi working pressure gasket have been difficult to overcome and required us to look and think from a different angle. Achieving qualification of the first of a new series of gasket designs that we intend to launch over the next year that incorporate our unique patented sealing technology has created a very positive outlook for Sub-drill and our ever-growing client base.”

Quality . Technology . Compliance

The introduction of Sub-drill’s first 20K rated Sub-X™ subsea ring gasket represents a substantial milestone in the development of a new series of Sub-X™ subsea ring gaskets. Sub-drill takes immense pride in supporting the Oil and Gas industry to safely push beyond traditional sealing limitations through cutting edge product innovation and development.

Jim Inglis, Commercial Director of Sub-drill stated, “Our ongoing commitment to product development is unwavering, and completing this additional step as part of a number of additional qualifications for our new series of Sub-X™ Subsea Gaskets will set a new level of expectation in subsea seal performance, with the same consistent high product quality of the existing Sub-X™ gasket range. Our patented seal technology has been vital in developing market leading seals for the Oil and Gas industry of today and the next generation of major equipment while maintaining and exceeding the requirements for compliance with the governing National Standards. Our clients recognise these commitments which have made us the subsea seal manufacturer of choice for our clients”.

As part of its ongoing commitment to innovation, Sub-drill continues to collaborate with major BOP, Connector, Wellhead, Riser and Production System equipment manufacturers to produce the next generation of market leading subsea equipment. For more information about Sub-drill’s latest product developments, please reach out for an informal discussion. Additionally, you can connect or follow us on Linkedin™ for updates on our product development and additional content, and may also sign up for our news via our website.

Read more at: https://www.sub-drill.com/sub-x-wellhead-bop-gaskets.html

Sub-X brochure: click here to view/download