Sub-drill’s Sub-X™ subsea ring gasket technology has developed and grown and became the World’s first fully qualified subsea gasket tested, qualified to API 17D and API 6A to PR2 including Annex F, witnessed by Lloyd’s Register.

Our unique PR2-F qualified range of subsea ring gaskets offers unrivalled quality and sealing technology in full compliance with the latest governing national standards.

Our global client base sees the Sub-X™ trademark as a symbol of quality, market-leading sealing technology and consistent performance. We take pride in providing the level of customer service our clients expect and respond quickly to any client requirements.

We continually seek out opportunities to improve our gasket technology, manufacturing methods and processes, and hold stock in support of our valued client base which has sealed our position as the subsea gasket manufacturer of choice.

UK Granted Patent 2608252

Sub-drill provide VX, VX-VT (VXT), VGX and VGX-VT (VGT) type gasket variants. Other gasket profiles available include AX and CX types. Please contact Sub-drill for further information and technical ratings on wellhead, connector, LMRP and riser gasket variants.

Quality

• UK manufacture

• Full product traceability

• Full in-house manufacturing control

• 100% CMM inspection

• Minimum of 12 individual quality control checks

• No compromise from raw material to packed product

• Field proven product over 30 years

• Ensure the end product is fit to bear the Sub-X™ brand trademark

Please click here to view and download.

Technology

• Unique patented gasket technology

• Developed from extensive research and development

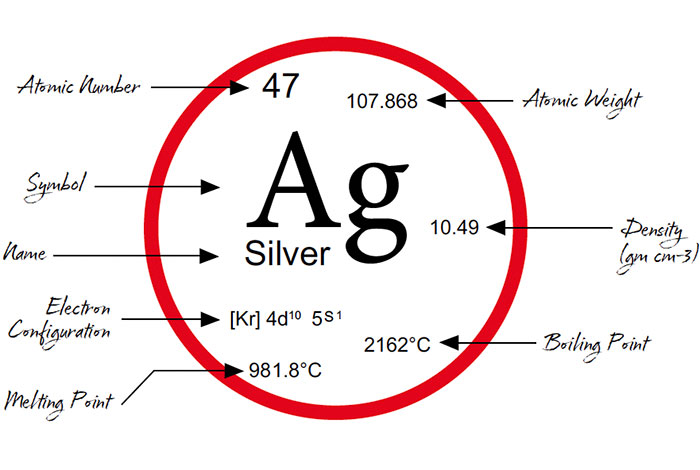

• Qualified proprietary silver plating and surface technology

• Silver improves the condition of the major equipment seal profiles, enhancing life span

• Silver maintains full metal-to-metal gas-tight sealing

• Silver removes risk of resin contamination posed by other surface coatings

• UK Granted Patent 2608252

Compliance

• Designed and qualified to API 17D / ISO 13628-4 and API 6A / ISO 10423

• 3rd party notifiable body Lloyds Register, independently reviewed and witnessed the entire qualification process and ensured exacting compliance.

• EPR testing carried out when the gasket is in its most fatigued state to ensure the integrity of the well under the most extreme conditions.

• Completed the required PR2-F qualification testing program specified by the governing international standards for all VX, VX-VT (VXT), VGX and VGX-VT (VGT) type gasket variants.

• Met the requirements of “The Offshore Installations (Safety Case) Regulations SI 2005/3117” and “The Offshore Installations and Wells (Design and Construction, etc.) regulations SI 1996/913” and all equivalent international regulations.