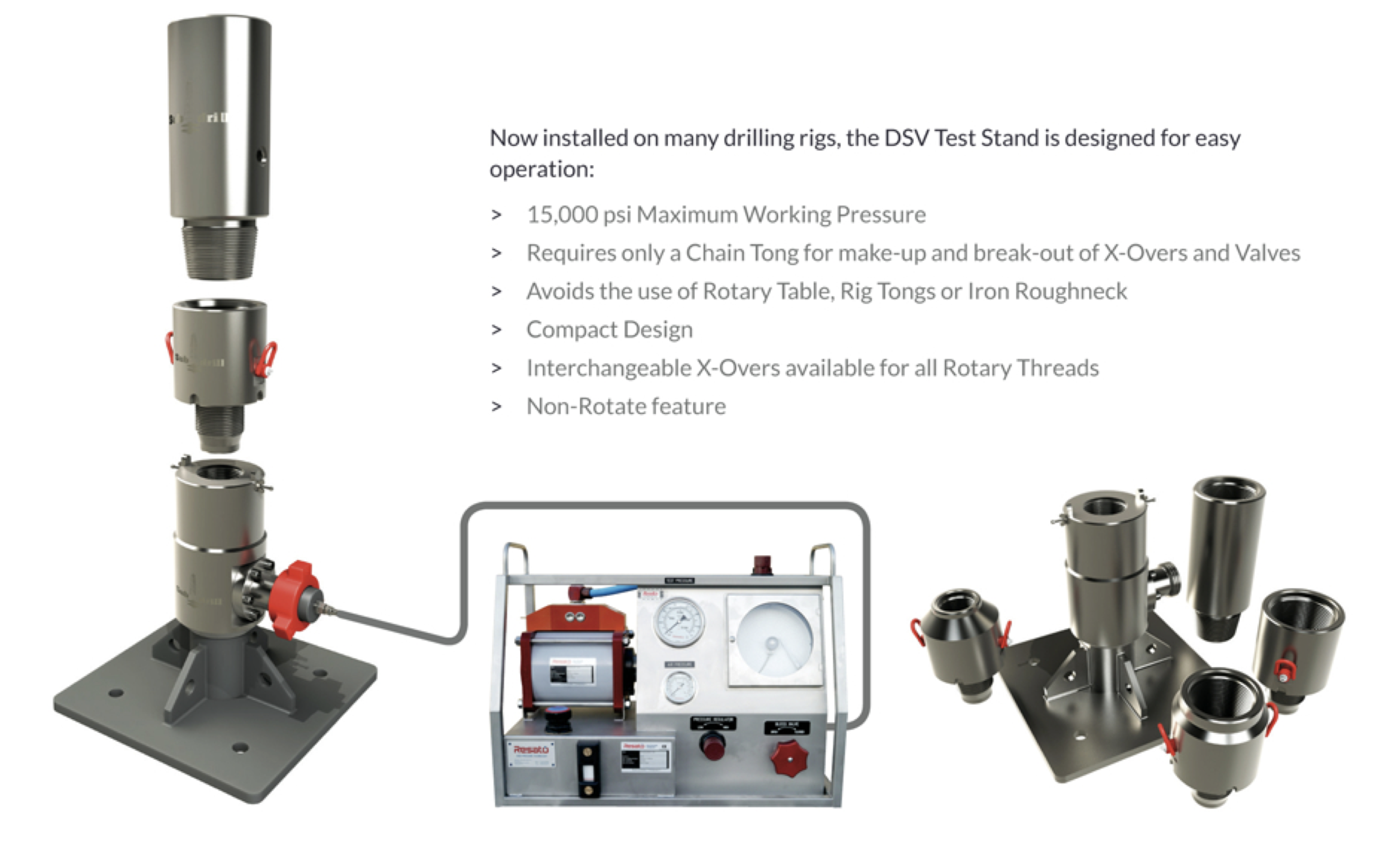

The Subdrill DSV™ Test Stand provides a quick, easy, pre-defined and safe method of testing Drill Stem Valves prior to installation in the string, without requiring the Rotary Table, Rig Tongs or Iron Roughneck.

Now standard protocol with a number of drilling contractors, the Subdrill DSV Test Stand has been designed with speed, efficiency and safety in mind. By utilising the DSV™ Test Stand, Drill Stem Valve testing can be carried out quickly and safely off-line in parallel with BOP testing or drilling. In addition, it is estimated that the operator will save approximately 2-3 hours during a routine rig BOP test.

Drill Stem Valve Testing

Drill stem valves are critical rig items and form part of the routine BOP equipment test cycle. Making sure that the valves are tested correctly and function properly under pressure is vital to the operational integrity of the drill-Stem. The Sub-drill DSV™ Test Stand can provide a reliable, quick and safe method for testing these valves prior to installation in the string, and includes the following features and benefits:

• 15,000 psi Maximum Working Pressure

• Requires only a Chain Tong for make-up and break-out of X-Overs and Valves

• Avoids the use of the Rotary Table, Rig Tongs or Iron Roughneck

• Compact design

• Interchangeable X-Overs available for Drilling & Tubing Rotary Threads

• Non-Rotate feature

• Tests off-line in parallel with BOP testing or drilling

• Saves 2-3 hours during a routine rig BOP test

Sub-Drill / DNV Design Verification

Sub-Drill / DNV Design Verification

• Test Pump with Integral Chart Recorder, designed for optimum use of the DSV™ Test Stand – compact, reliable and easy to use

• Rig Air 100 psi

Please click here to view and download.

Sub-Drill run a 'lunch & learn' for companies that are looking to find out more about specific products and services. Please click here to make your enquiry.